Several people bought a Proxxon MF70 milling machine, so here's a small tips & tricks exchange topic. To kick-start the discussion the intro from my own experience this wel:

------------

I just bought the Proxxon MF70 Milling Machine (27110), a tiny machine that can be upgraded (or bought) as a CNC machine and offers a much higher rpm than my drill press or lathe: it goes up to 20,000 rpm. I was never able to drill anything below 0.5mm without drills breaking and more or less gave up on that idea without a watchman's lathe or equivalent, until Marijn van Gils showed his brand-new MF70 could drill almost to 0.1mm in brass (See his

HMS Victory Vs Le Redoutablebuild). As the mill is quite affordable and I no longer have to pump all my savings in my recently completed audio project, I bought one as well.

So I did use the

Drill Press with a compound table (27100), a precision machine vice (24260) and a nice dividing head (24264). <em>But</em>, the rate of revolutions is low and the entire setup is quite flexible and as such not precise. More important, it does not have a proper collet system but uses a large three-jaw chuck that is inherently terrible for fine work.

Imagine my surprise that the MF70 does not have a proper collet system either; it uses the Micromot collet system. That's fine, but these cannot old larger objects such as Proxxon's own edge finders. For my small lathe, Proxxon failed to deliver a proper collet system for the tail stock too, though that was solved by

brutally cutting an MC11 ER11 collet chuck. For the mill this is not an option as the spindle doesn't use an MC11 system, but after minor search efforts I found a replacement part at

USOVO; a new tuning spindle with an ER-11 chuck and it even comes with a small installation manual. Rejoice!

I do wonder why Proxxon seem to be content with their tools not being able to use the entire range of tool mods and expansion sets among them, but at least now I could use the Edge Finder Set (24434) <em>that doesn't fit the original MF70</em> to align the vice properly and to help finding, well, edges. I did perform some tests with the Micromot collets and these did hold

some of my drills perfectly centered, so I can image

some people not needing the ER11 collets. I added an extra collet set in a nice box (24154, noticed the Usovo set too late) plus an additional vice (the vice vice). With these options the mill became roughly twice as expensive and I forgot to buy cutters as

these are not included---not even one---but small cutters can be bought as small as 0.2mm at other stores. The mill did come with a cross table (27100) and a set of step clamps (24256).

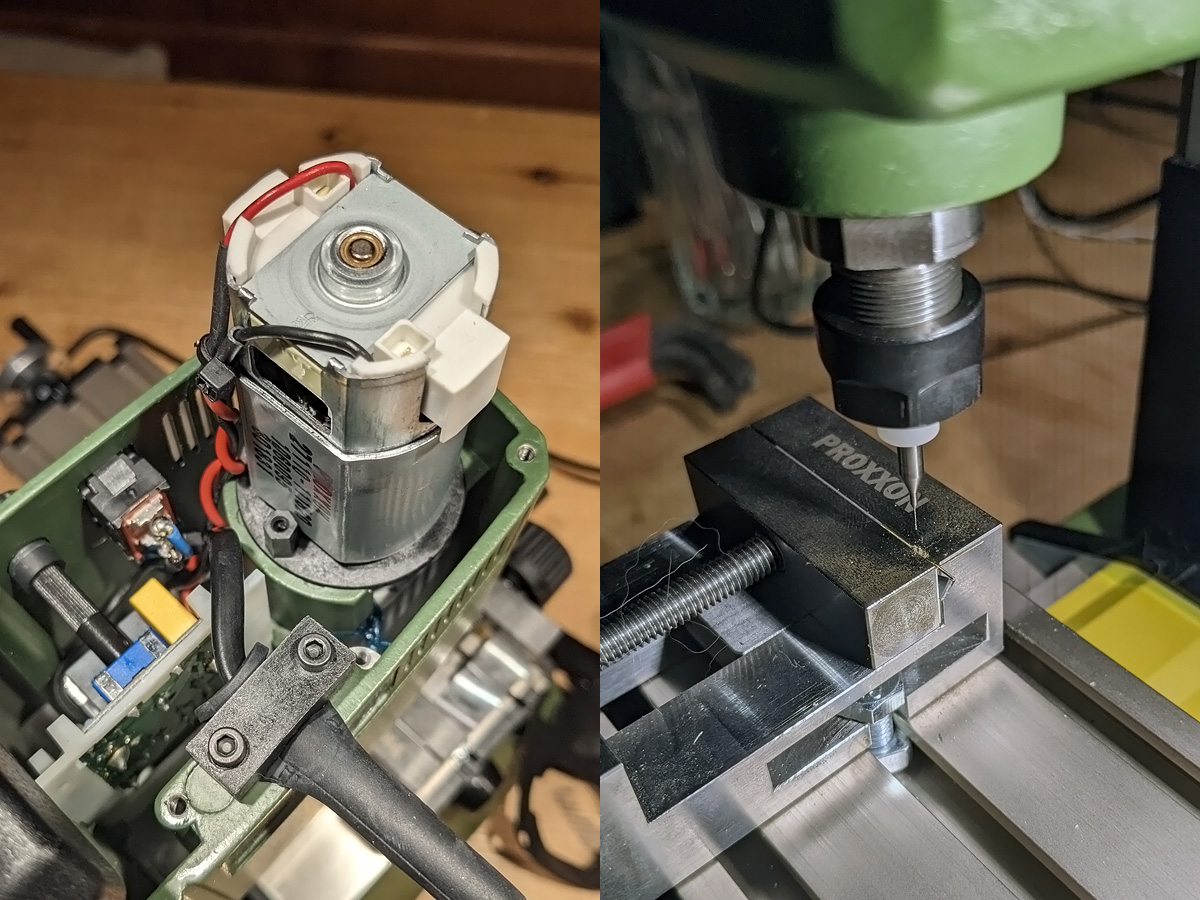

Installing the new spindle took about half an hour. I used my sturdy Gorilla-proof 1.5mm Hex wrench the remove the motor plate screws that have been tightened very well and T10 (I think) Torx driver to remove a screw holding the spindle in place. The Usovo spindle comes with two bearings but I kept the bearing of the existing spindle. The set does not come with a tool to (un) clamp the nut or hold the ER11 spindle; I had one for the ER-11 tailstock of my lathe so don't forget to order one if you purchase this new spindle. If you buy the Proxxon collett set or one from Usovo (slightly more expensive but contains 13 over them, the Proxxon only 7), you may also want to order a 3.175mm ER-11 collet separately, the default size of many of my drills.

Several people bought a Proxxon MF70 milling machine, so here's a small tips & tricks exchange topic. To kick-start the discussion the intro from my own experience this wel:

------------

[img]https://ontheslipway.com/wp-content/uploads/2022/01/MF70_01.jpg[/img]

I just bought the Proxxon MF70 Milling Machine (27110), a tiny machine that can be upgraded (or bought) as a CNC machine and offers a much higher rpm than my drill press or lathe: it goes up to 20,000 rpm. I was never able to drill anything below 0.5mm without drills breaking and more or less gave up on that idea without a watchman's lathe or equivalent, until Marijn van Gils showed his brand-new MF70 could drill almost to 0.1mm in brass (See his [url=http://www.shipmodels.info/mws_forum/viewtopic.php?f=59&t=167367]HMS Victory Vs Le Redoutable[/url]build). As the mill is quite affordable and I no longer have to pump all my savings in my recently completed audio project, I bought one as well.

So I did use the [url=https://ontheslipway.com/proxxon-drill-press/]Drill Press[/url] with a compound table (27100), a precision machine vice (24260) and a nice dividing head (24264). <em>But</em>, the rate of revolutions is low and the entire setup is quite flexible and as such not precise. More important, it does not have a proper collet system but uses a large three-jaw chuck that is inherently terrible for fine work.

[img]https://ontheslipway.com/wp-content/uploads/2022/01/MF70_02.jpg[/img]

Imagine my surprise that the MF70 does not have a proper collet system either; it uses the Micromot collet system. That's fine, but these cannot old larger objects such as Proxxon's own edge finders. For my small lathe, Proxxon failed to deliver a proper collet system for the tail stock too, though that was solved by [url=https://ontheslipway.com/a-small-improvement-of-the-proxxon-pd230-e/]brutally cutting an MC11 ER11 collet chuck[/url]. For the mill this is not an option as the spindle doesn't use an MC11 system, but after minor search efforts I found a replacement part at [url=https://www.usovo.de/en]USOVO[/url]; a new tuning spindle with an ER-11 chuck and it even comes with a small installation manual. Rejoice!

I do wonder why Proxxon seem to be content with their tools not being able to use the entire range of tool mods and expansion sets among them, but at least now I could use the Edge Finder Set (24434) <em>that doesn't fit the original MF70</em> to align the vice properly and to help finding, well, edges. I did perform some tests with the Micromot collets and these did hold [i]some [/i] of my drills perfectly centered, so I can image [i]some [/i]people not needing the ER11 collets. I added an extra collet set in a nice box (24154, noticed the Usovo set too late) plus an additional vice (the vice vice). With these options the mill became roughly twice as expensive and I forgot to buy cutters as [i]these are not included[/i]---not even one---but small cutters can be bought as small as 0.2mm at other stores. The mill did come with a cross table (27100) and a set of step clamps (24256).

[img]https://ontheslipway.com/wp-content/uploads/2022/01/MF70_03.jpg[/img]

Installing the new spindle took about half an hour. I used my sturdy Gorilla-proof 1.5mm Hex wrench the remove the motor plate screws that have been tightened very well and T10 (I think) Torx driver to remove a screw holding the spindle in place. The Usovo spindle comes with two bearings but I kept the bearing of the existing spindle. The set does not come with a tool to (un) clamp the nut or hold the ER11 spindle; I had one for the ER-11 tailstock of my lathe so don't forget to order one if you purchase this new spindle. If you buy the Proxxon collett set or one from Usovo (slightly more expensive but contains 13 over them, the Proxxon only 7), you may also want to order a 3.175mm ER-11 collet separately, the default size of many of my drills.