Thanks guys!

LE BOSCO wrote:

three qualifier for your thread Marjin ,inventiveness, dexterity, friendliness

Dang! I was going for arrogance and abusiveness…

blacman wrote:

May I ask how did you manage to create conical masts? It is just dremel and sand paper?

Almost!

The problem with the Dremel is that anything longer than 1cm or so starts to twist and tremble, making it impossible to get nice and regular, or even any, results.

Jim Baumann told me this little trick in Telford last year: stabilize the wire in a small groove in the workbench.

My workbench is in the living room and I want to keep it in one piece, so I made the groove in a piece of MDF. I simply used a saw, guided by a metal ruler:

The groove is very simple and shallow, just enough for the brass wire to get caught in.

Behind the fresh groove, you see some used ones. The metal wire does erode the grooves when spinning, so I had to make several new ones. The upside to the MDF is that the brass wire doesn't heat up too much while spinning in it.

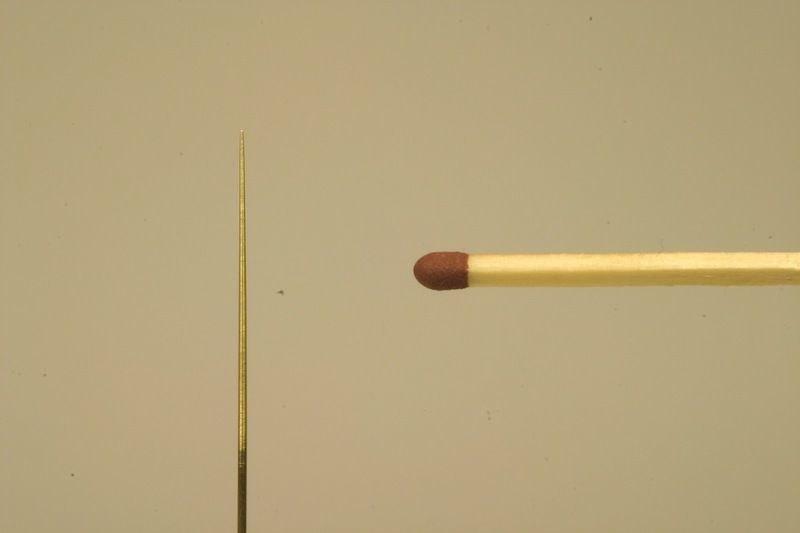

So then I spin the wire in the Dremel, lay it down gently in the groove, and press a file down on it (sandpaper glued to a thick piece of plastic sheet works well also):

By moving the file up and down, and regularly checking the wire, this kind of results can be achieved:

After adding some PE and tubing details:

The booms are also tapered this way, but to a lesser degree. I also added a small taper to them towards the mast by first turning the main taper, cutting the wire to length, turning it around in the Dremel and turning again.

I was surprised how well this technique worked, and how easy it was to get really nice results.

Just be careful with yours eyes; the wire can break at the fitting of the Dremel and get launched in the air at high speed.

Cheers!

Marijn